Processing Equipment

What is processing?

Materials Processing in Material Science includes a series of steps used in the manufacture of raw materials into finished goods. At the MILL, the Processing Team uses multiple techniques to process materials, including 3D printing (additive manufacturing), sewing and embroidery (textiles), ball mills and furnaces (ceramics processing), etc.

The processing team is led by Sophia Anderson. Please contact Sophia for more information!

If there is a specific piece of equipment you would like training on, please email the respective Technical Officer (TO) for that piece of equipment.

The list of Technical Officers can be found here.

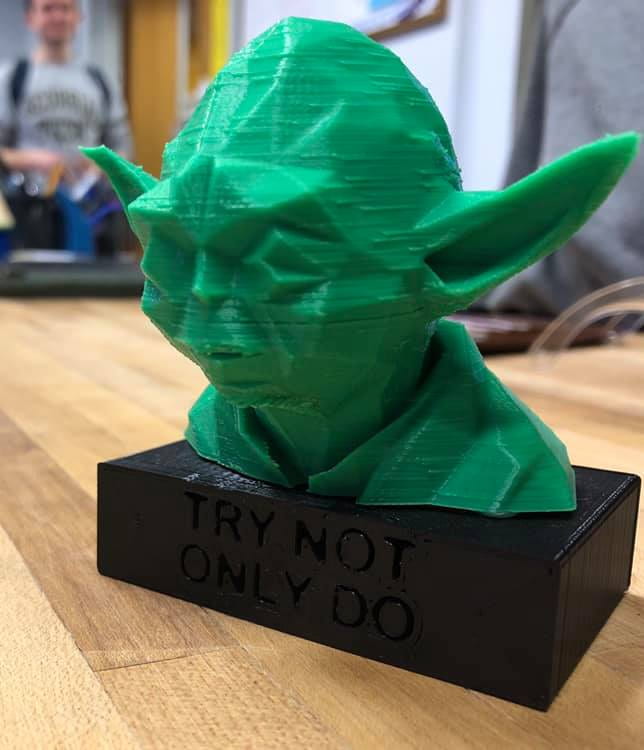

Photo Gallery

Equipment Directory – Jump to Your Desired Equipment

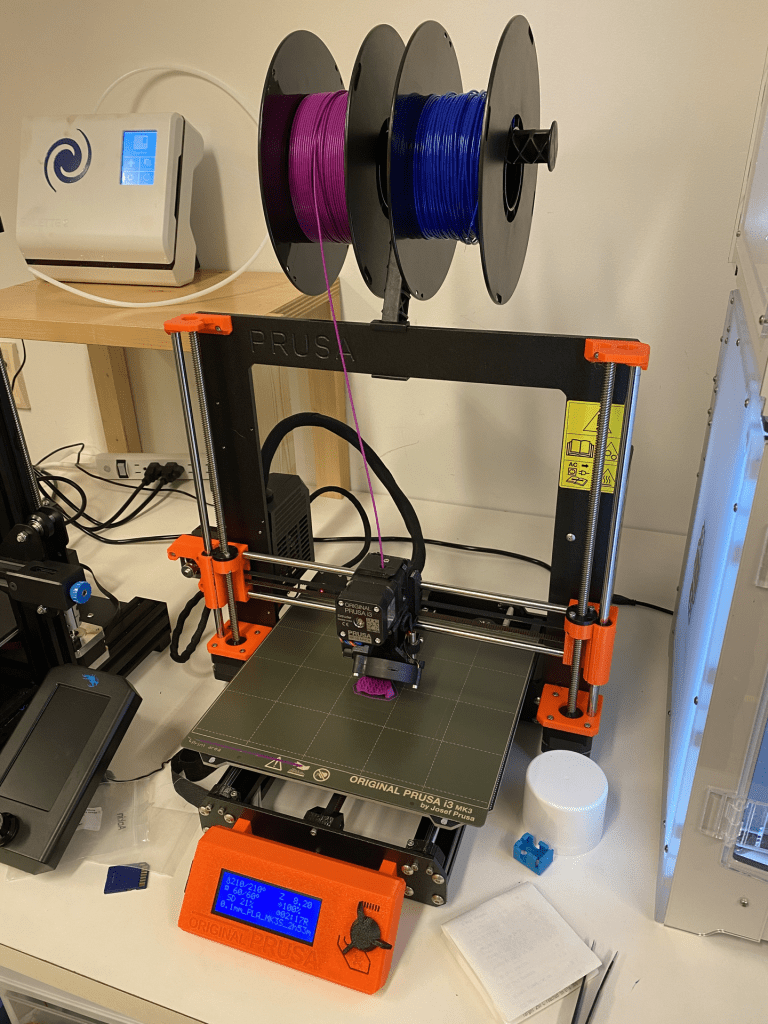

Prusa i3 3D Printers

Located in Main Lab (167)

SOP: Prusa i3 MK3S

Prusa i3 is an FDM printer for 3D printing. It has a maximum print temperature of 300C so it is capable of a range of higher temperature materials. The materials that can be printed in Prusa include PLA, TPU, PP, etc. It has great reliability and produces higher resolution prints.

Sign In / Reserve Here

BambuLab XIE Carbon 3D Printers

Located in Main Lab (167)

SOP: BambuLab XIE Carbon

The Bambu Lab X1E Carbon is a high-performance 3D printer designed for precision and reliability. Featuring an enclosed chamber, active heating, and advanced carbon fiber reinforcement, it excels at printing high-temperature and engineering-grade materials. With AI-driven calibration, multi-filament support, and composite compatibility, the X1E Carbon is ideal for demanding research and prototyping applications.

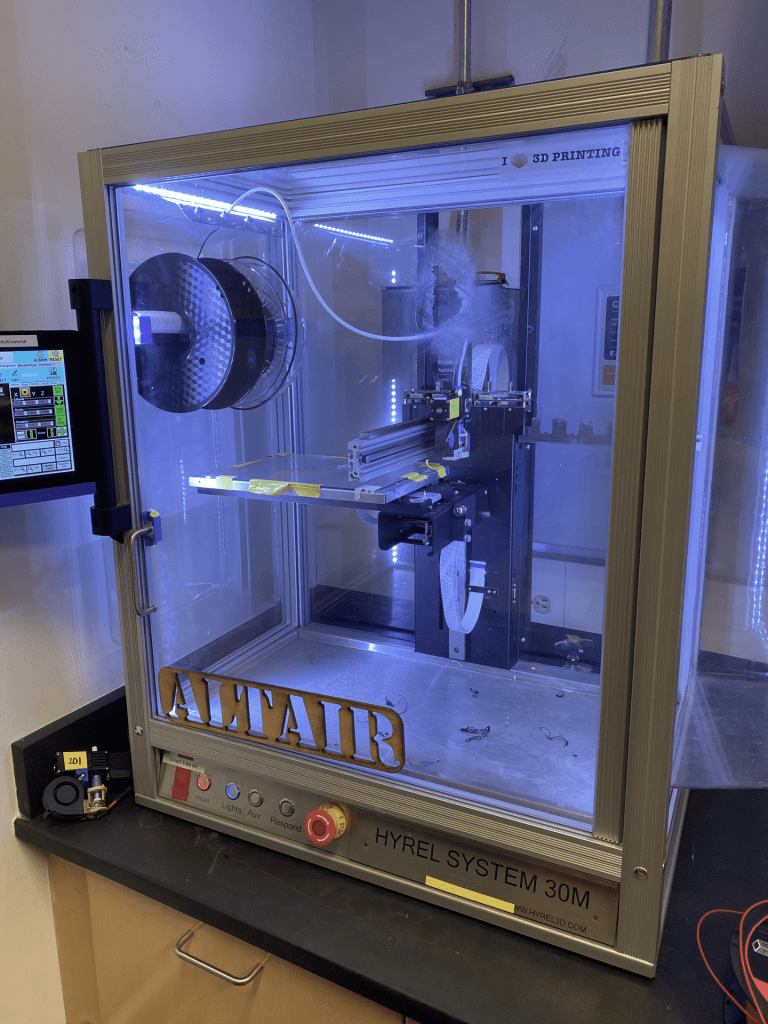

Hyrel 3D Printers

Located in Processing Lab (150)

SOP: Hyrel 3D printer

Hyrel 3D printers can print a large range of materials. The Repetrel control software allows for great flexibility in varying processing parameters. Print in just one material, or experiment with combinations; the heads are modular and each printer can support up to four heads at once.

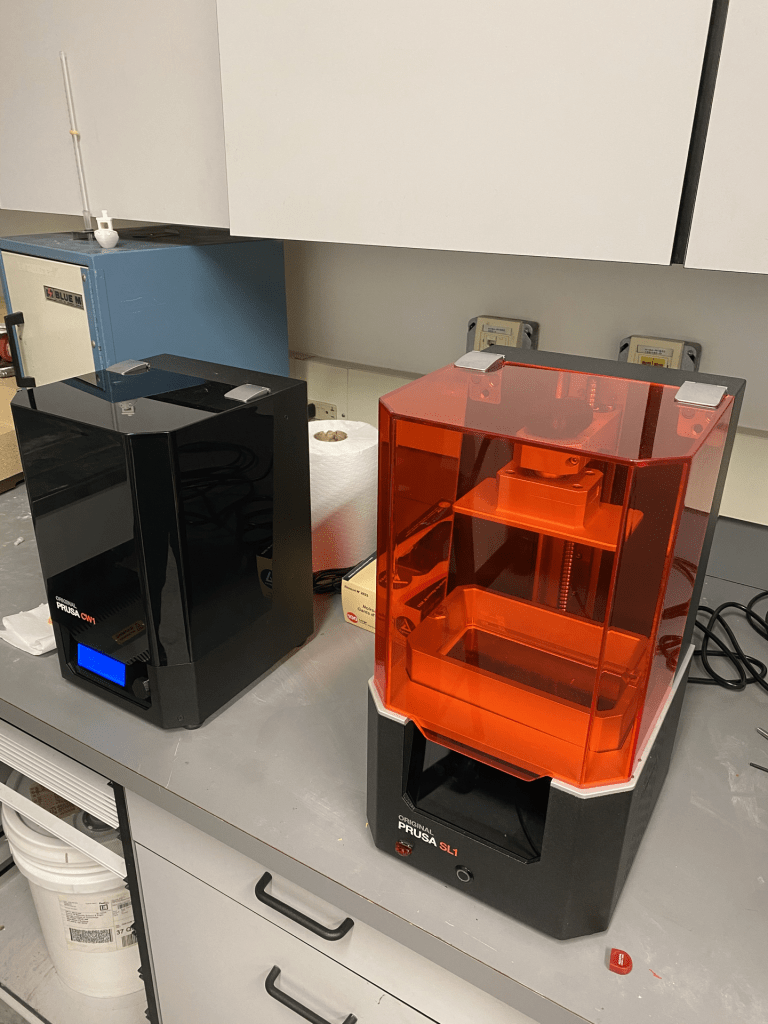

Prusa Resin Printer

Located in Advanced Prototyping Lab (150)

SOP: Prusa SL1 & CW1

The Prusa Resin Printer implements stereolithography (SLA) printing by curing layers of thermoset resin using UV light.

Formlabs 3+ Resin Printer

Located in Advanced Prototyping Lab (150)

SOP: Formlabs 3+ Resin Printer

The Formlabs 3+ utilizes a stereolithographic printing technique by curing resin using a UV light source.

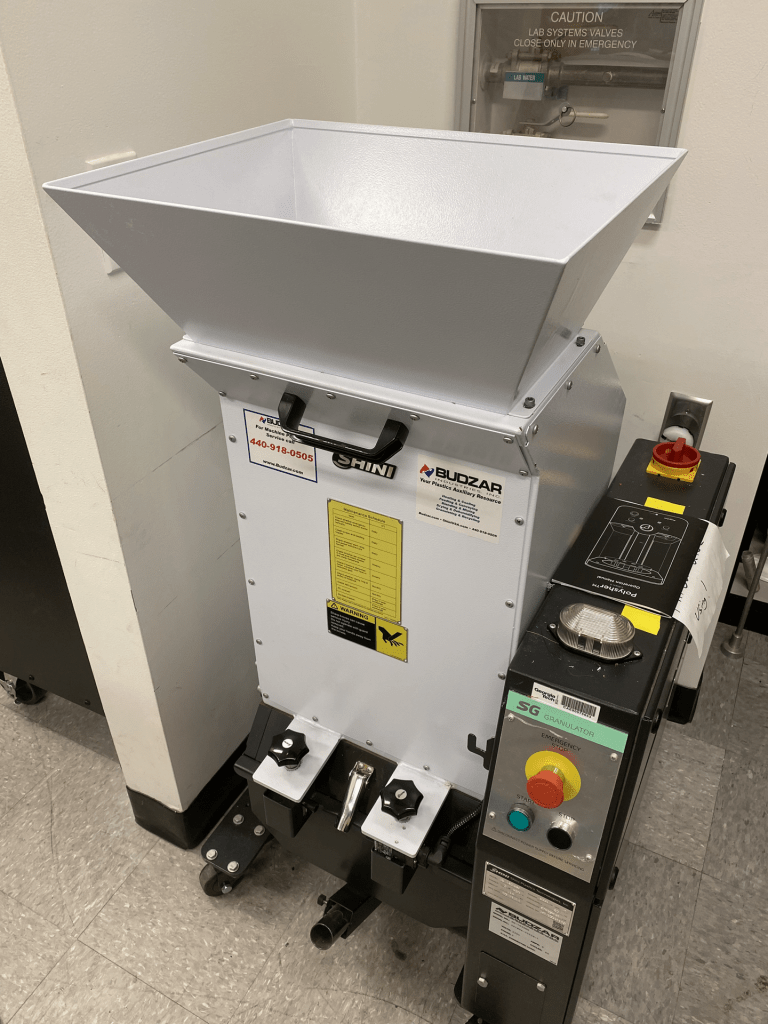

Granulator

Located in Main Lab (164)

Granulator is used by the MILL to break down old 3D prints into smaller pieces so that the material can be recycled using the filament maker in Love 167. The Sustainability L&D team is primarily working on this project. Learn more about Sustainability here.

Filament Maker

Located in Main Lab (167)

SOP: 3devo Composer 450 Filament Maker SOP

The 3devo is used to create filaments that can be used in 3D printing. The extruder takes granules of polymer(s) mainly from the granulator located in Love 164, heats them, forms them into a strand of filament, and spools the filament. Our filament maker is used in conjunction with the Sustainability L&D team. Learn more about Sustainability here.

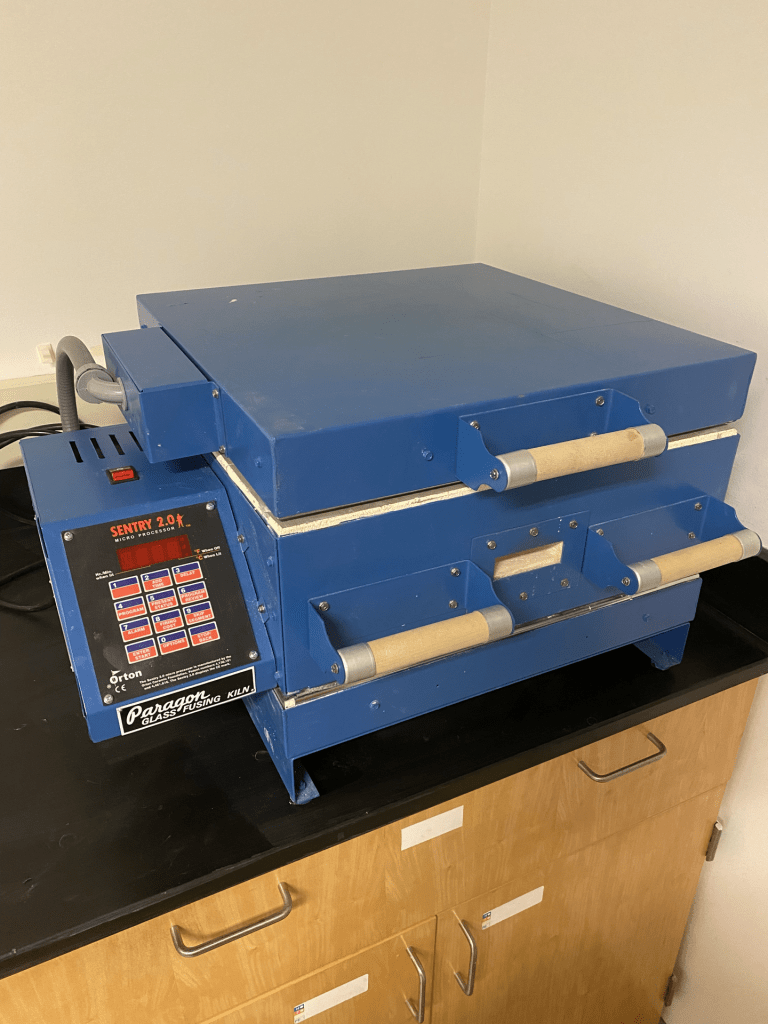

Glass Kiln

Located in Main Lab (174)

SOP: Paragon Fusion CS14D Glass Kiln

The glass kilns are used by the Science of Art team for glass fusing projects and events. Learn more about SOA here.

Cricut Vinyl Cutter

Located in Main Lab (164)

SOP: Cricut Maker 3 Vinyl Cutter

The Cricut is used to cut vinyl, paper, and other flat materials into desired shapes.

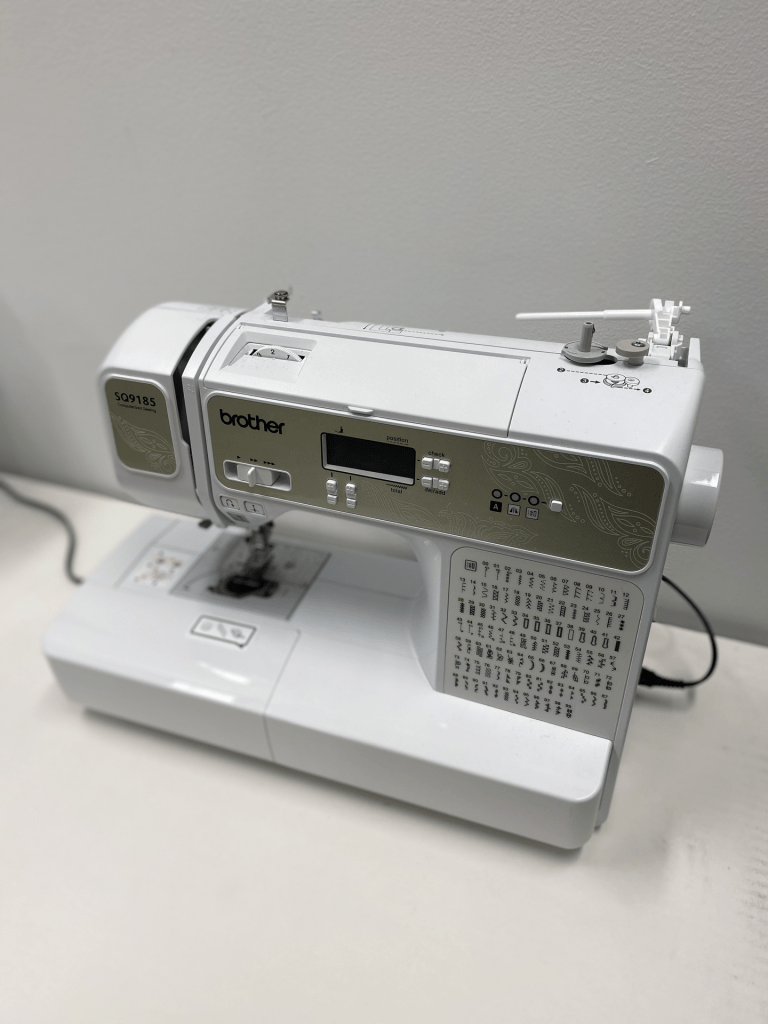

Brother Sewing Machine

Located in Main Lab (164)

SOP: Brother SQ9185 Sewing Machine

The sewing machine is used to sew fabrics and materials together with a thread. It is used in conjunction with the Textiles L&D team. Learn more about Textiles here.

Janome Sewing Machine

Located in Main Lab (164)

Janome Embroidery Machine

Located in Main Lab (164)

SOP: Janome MB7 Embroidery Machine

The embroidery machine is used to create patterns on textiles. It is used in conjunction with the Textiles L&D team. Learn more about Textiles here.

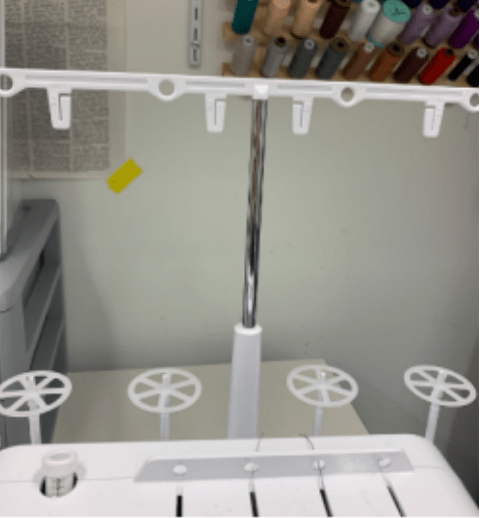

Serger

Located in Main Lab (164)

The Serger is used to create a secure and clean edge for any seam on a piece(s) of fabric.

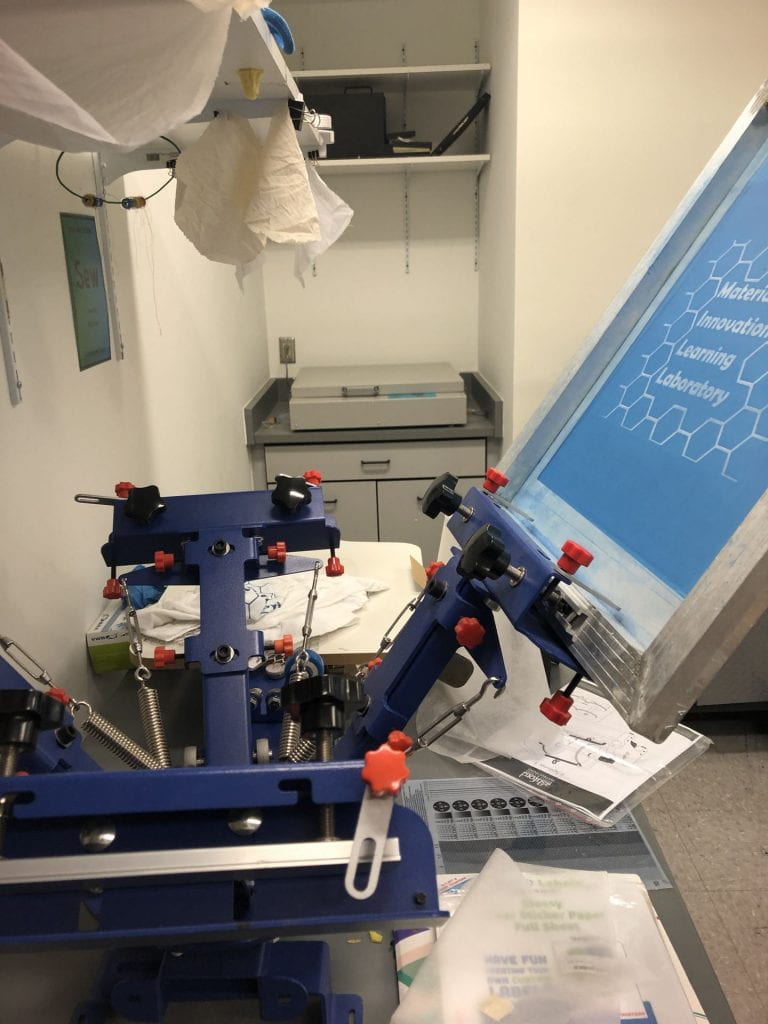

Screen Printer

Located in Main Lab (164)

SOP: Screen Printer

The screen printer uses a printing technique where a mesh is used to transfer ink or dye onto a substrate, except in areas made impermeable to the ink by a blocking stencil. It is commonly used in conjunction with our heat press. If interested in using this piece of equipment, please contact the processing team’s CTO.

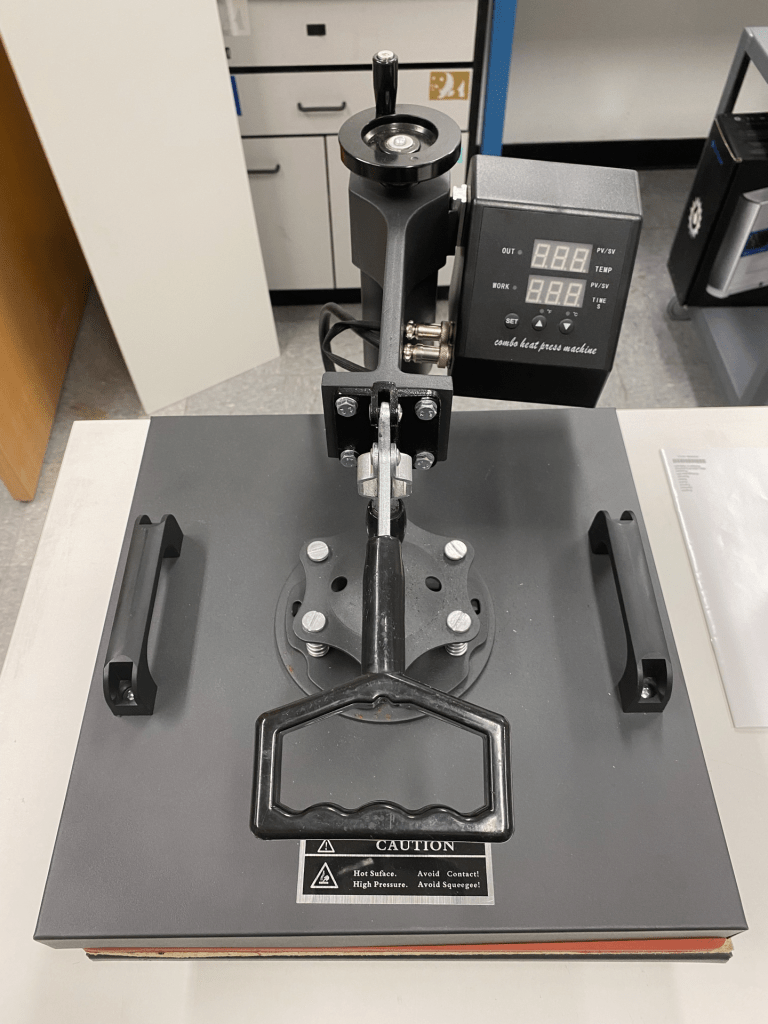

Heat Press

Located in Main Lab (164)

SOP: F2C Pro Heat Press

The F2C Pro heat press is used to stamp designs onto various textiles, including t-shirts. It is commonly used in conjunction with our screen printer. If interested in using this piece of equipment, please contact the processing team’s CTO.

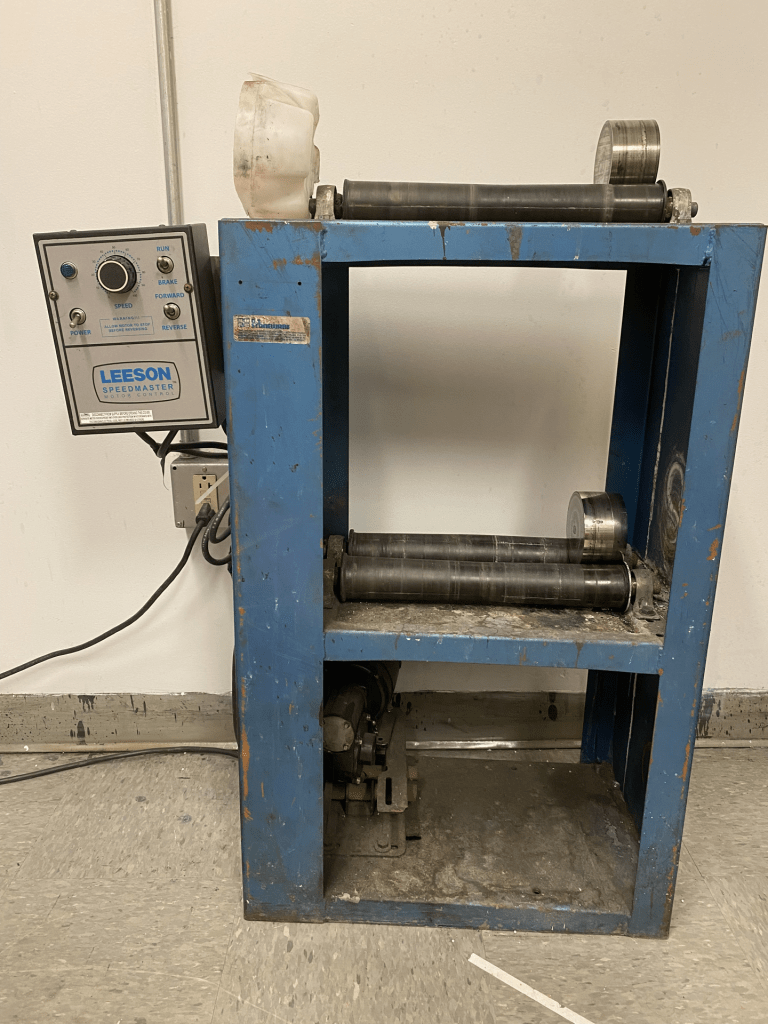

Rolling Ball Mill

Located in Ceramics Lab (369)

Status: Currently Under Maintenance

SOP: US Stoneware 784AVM Rolling Ball Mill

Use the MILL’s US Stoneware rolling ball mill for comminution. This has a variety of applications in powder processing where smaller powder sizes may be preferable for solid-state diffusion. If interested in using this piece of equipment, please contact the processing team’s CTO.

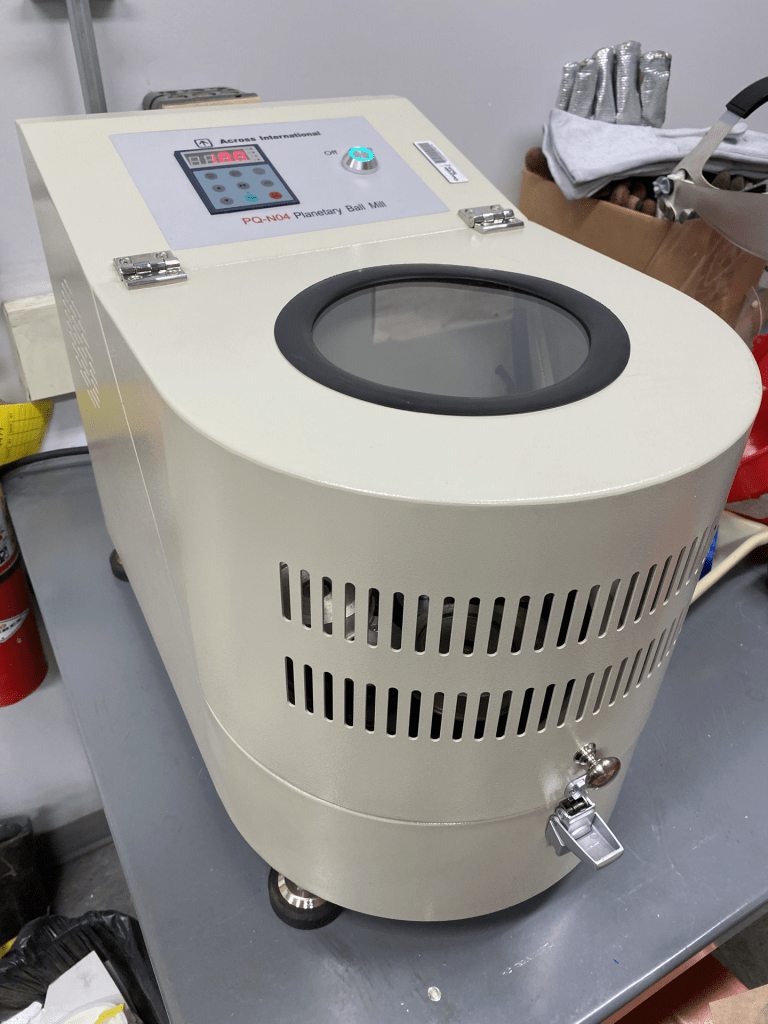

Planetary Ball Mill

Located in Ceramics Lab (369)

Status: Currently Under Maintenance

SOP: Across International PQ-N04 Planetary Ball MILL

The Across International planetary ball mill is used when even finer particle sizes are necessary when compared to our rolling ball mill. If interested in using this piece of equipment, please contact the processing team’s CTO.

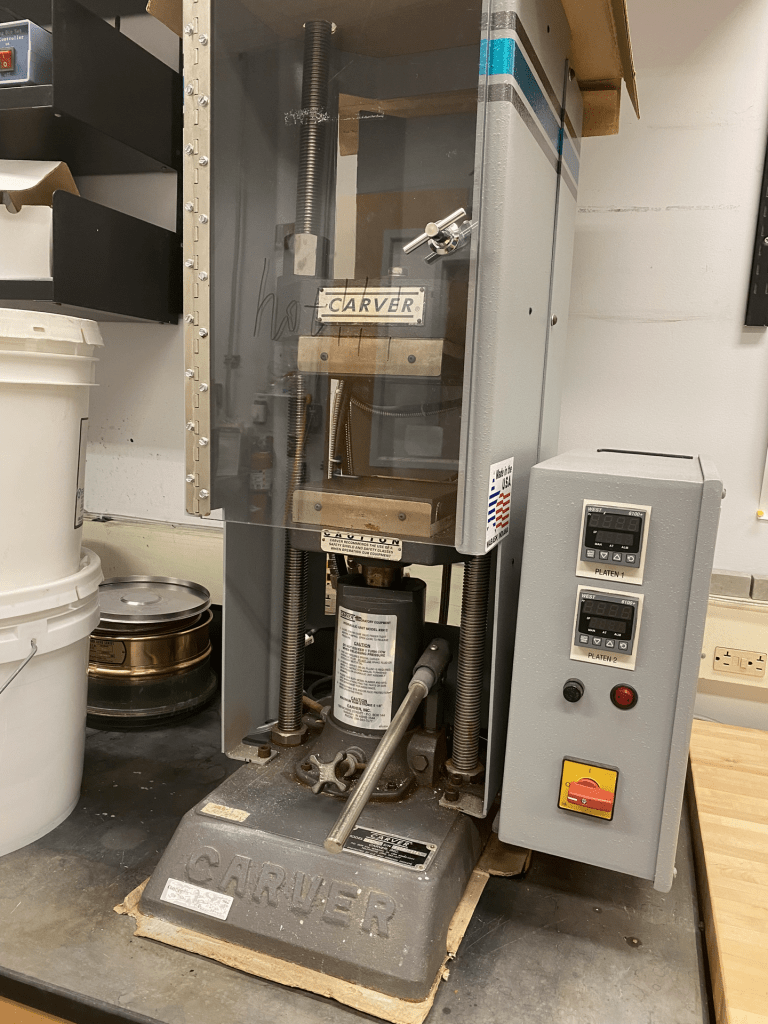

Uniaxial Press

Located in Ceramics Lab (369)

Status: Currently Under Maintenance

SOP: Carver 3851 Uniaxial Press

The uniaxial press is used to sinter a ceramic or cut a piece of material using a die. The plates of the press can be heated to a user-specified temperature. If interested in using this piece of equipment, please contact the processing team’s CTO.

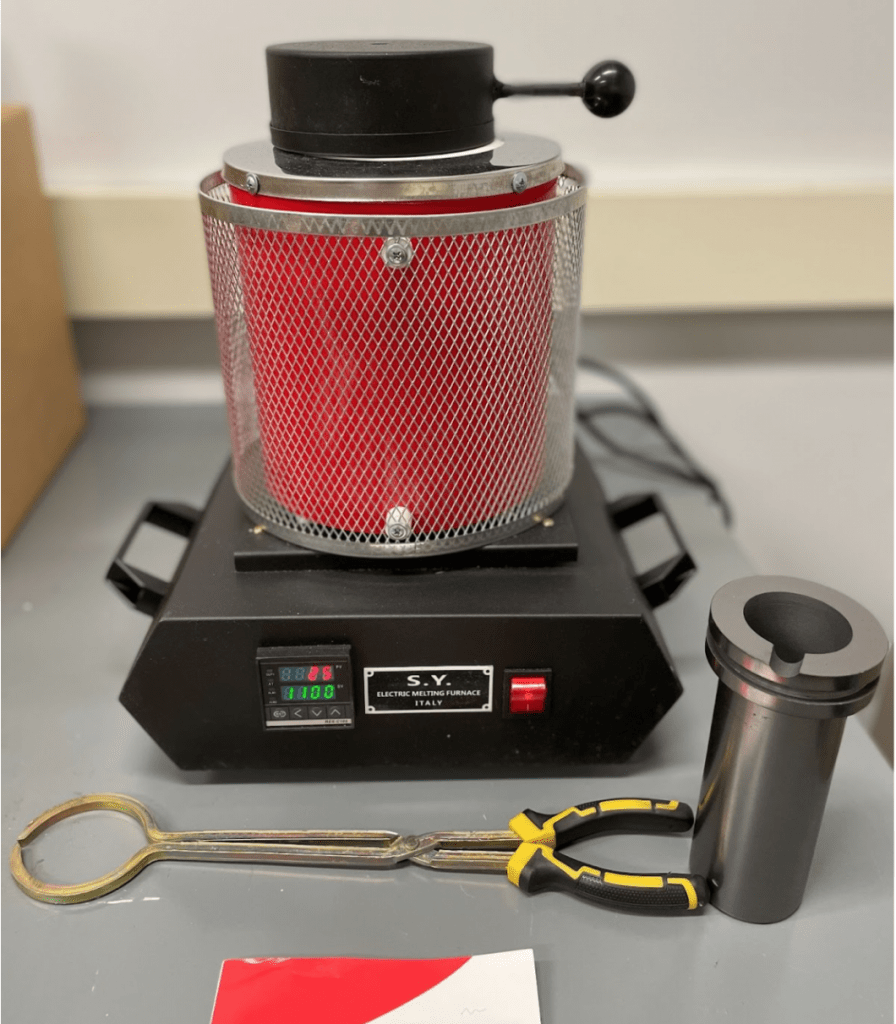

Melting Furnace

Located in Ceramics Lab (369)

Status: Currently Under Maintenance

SOP: REX-C100 Electric Melting Furnace

The melting furnace is used to melt metals like Cu (1084.62°C), silver (961.78°C), gold (1064.18°C), and noble metals. If interested in using this piece of equipment, please contact the processing team’s CTO.

Button Maker

Located in Main Lab (164)

SOP: Cricut Button Maker 3 SOP

The button maker is used to create custom buttons or magnets by crimping circular cutouts, vinyl, and premade shells together. Designs are scaled and cut to specific sizes, then assembled and pressed using the machine’s lever mechanism.

Sublimation Printer

Located in Main Lab (164)

High Temperature 3D Printer

Located in Advanced Prototyping Lab (150)

High-Temperature 3D Printer Available for Relocation

The High-Temperature 3D Printer is currently seeking a new lab space. Professors interested in housing and utilizing this equipment are welcome to inquire. Please reach out to themillgt+CEO@gmail.com more details.

Vacuum Former

Located in Advanced Prototyping Lab (150)

SOP: Coming Soon

Rug Tufter

Located in Advanced Prototyping Lab (150)

SOP: Coming Soon