Spotlight

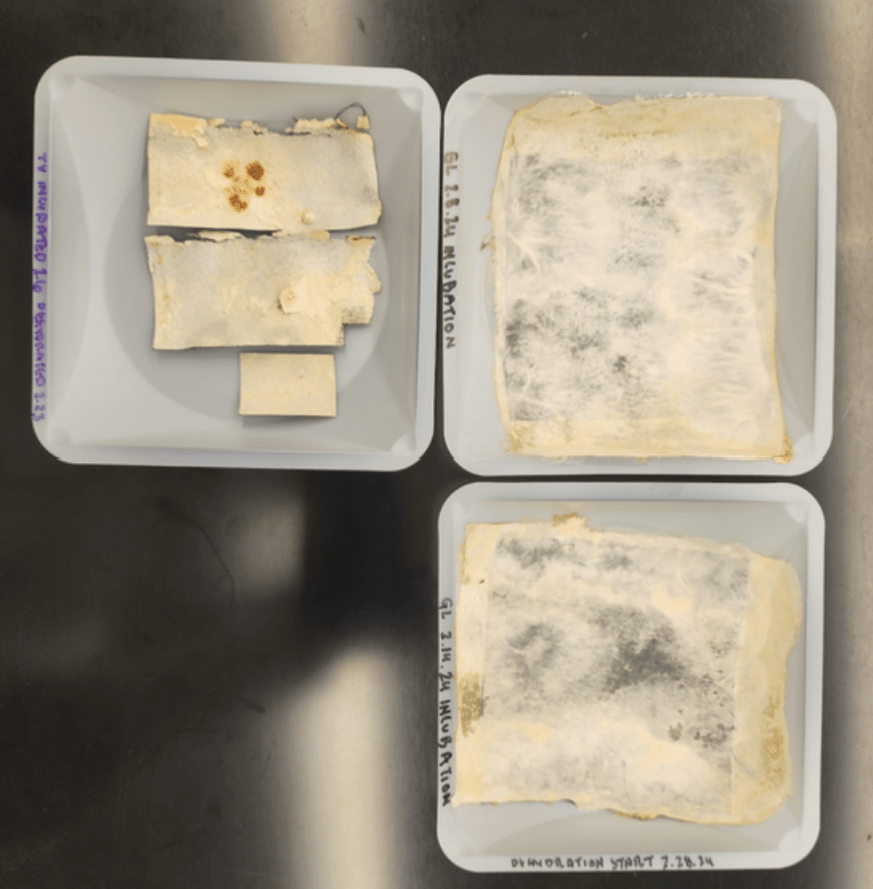

Even before arriving at Tech, there was an idea Mya knew she wanted to explore: sustainable fashion. Her interest in sustainability began with oil spills and how she “found it strange that oil spills were being cleaned with plastic, which is also made of oil!”. She began to more carefully examine the intersection between sustainability and her other passions, notably the harmful effects of fast fashion. She wanted to reduce her fashion-related carbon footprint, and the most obvious answer to her was sustainable fabrics. She even made parts of her high school prom dress out of kombucha fabric, a substance with similar properties to vinyl. Her journey for more sustainable materials with properties similar to normal fabric ultimately led her to mycelium. Her goal is to create a mycelium culture that will fully recycle old fabric by eating it and then process the resulting mycelium growth into new fabric.

When Mya finally arrived on campus her freshman year, she hit the ground running. She knew she wanted to create better mycelium cloth, but there was not a lab or project on campus dedicated to this yet. Instead, she took the initiative and cold emailed professors asking to use their space to continue her research.

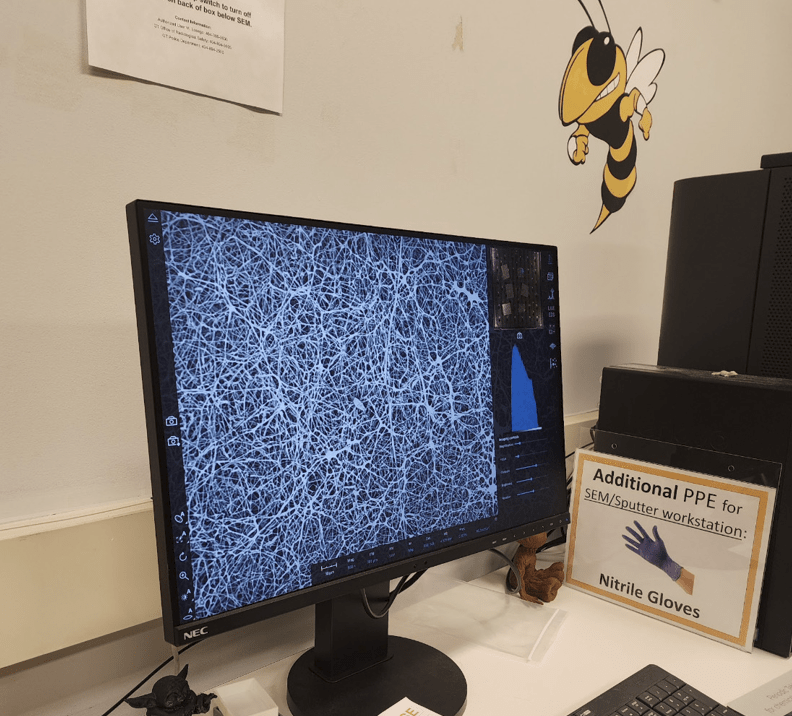

Mya first learned about the MILL through a Science of Art event at the beginning or her first year and later asked Eli Winterscheidt, the then MILL CEO, if she could still apply to be a staffer even though the application date had passed. Eli made it clear that “it’s never too late,” and Mya shortly joined the MILL’s Processing team. In the forming of her initial prototypes, Mya took full advantage of the equipment available to her, using the heat press in the MILL’s processing room to flatten and kill the mycelium growth and turn it into her mycelium fabric. The resulting fabric more closely mimics the properties/texture of leather than a stereotypical woven fabric. Mya was also grateful for the expanded access hours being a MILL staffer gave her, especially since she would often find herself in the MILL well past midnight as she tried to further refine her mycelium cloth.

In addition to the equipment and research space, the MILL provided Mya with an expansive network of undergraduates, graduates, and professors who could advise and otherwise support her in her research. There, Mya met Helen, the L&D Textiles team lead, who Mya thought “was a great resource to find other people with the same interest in sustainable fashion.” The MILL’s faculty advisor Dr. Losego has also been indispensable in Mya’s research, acting as an advisor throughout the process.

In Fall 2022 and Mya’s first semester at Tech, Mya joined CreateX along with Irene and Pratt who are both in the same year as Mya. CreateX is Tech’s startup launchpad, allowing students to gain experience as entrepreneurs while exploring ideas they believe will enact positive change in the world. By Spring 2022, they had shifted their focus from mycelium that would simply eat old fabric to mycelium that would still eat the scrap/unusable fabric but allow for processing of the mycelium growth into new fabric. By Spring 2023, the team had made their first full-fledged garment from the processed mycelium fabric, but they know the road ahead of them is still long.

Mya and her team’s involvement in CreateX has helped with the development process, teaching them how to be an entrepreneur and how they might commercialize the mycelium cloth in the future. Mya’s project even made an impact on Rahul Saxena, the CreateX director, who invited Mya to present before members of Congress and separately the GT President Advisory Board.

To Mya, this experience has felt a bit surreal at times. “It’s so crazy because in [the MILL], it can feel more like arts and crafts. People wanting to see it succeed feels so cool,” Mya remarked.

At the CreateX demo day, Mya and her team received numerous pieces of advice from attending graduate students on how they might further develop their product and improve their product pitch. Mya and her team also attended Launchpad, the Industrial Design student showcase, where students even bought some of the mycelium fabric prototypes from them, surprising Mya. The students utilized Mya’s mycelium cloth in a variety of ways from making shoes, sewing a blouse and skirt set, and even lining the inside of a tool box which Mya had never considered before.

Right now, Mya is working on creating a more balanced workload for herself and cutting back on her late night MILL research sessions. Mya said she’s “taking smaller bites, so [she doesn’t] choke” and is instead focussed on dividing the work between her team of six plus members which includes undergraduate, graduate, and PhD students. Her group is still in the process of developing a mycelium culture that can fully break down old fabric since their existing culture can only do so partially. In the future, Mya hopes to use other equipment in the MILL like the measurement room’s numerous mechanical testers to further characterize the mycelium fabric, compare collected data to existing fabrics like natural leather, and identify potential areas for performance improvement.